Your cart is currently empty!

How we make our things

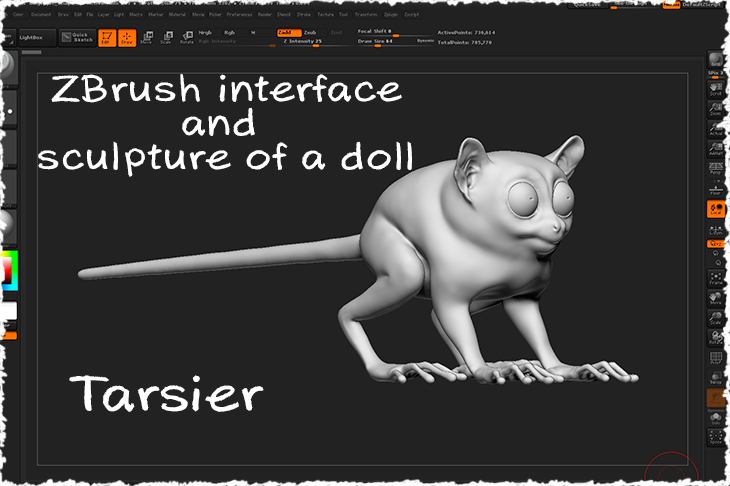

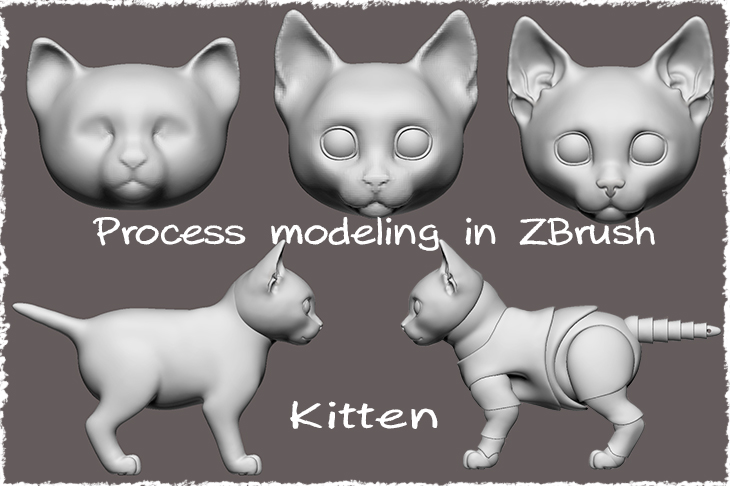

A 3D BJD doll is a traditional ball-jointed doll, but the model is created in a 3D editor for further printing on a 3D printer. We use ZBrush for this.

We first create the sculpture of doll, then it is divided into separate parts. We make joints and channels for a string in these parts. And we also make technical openings for cleaning out the powder from the cavities after printing. It is very important to maintain a balance between anatomy, aesthetics and mobility of the dolls.

When all the parts are ready, they are prepared for printing on a 3D printer. Preparing for printing consists in fitting parts to selected physical dimensions and specific placement of parts in the container of the printer in order to minimize visible printing traces.

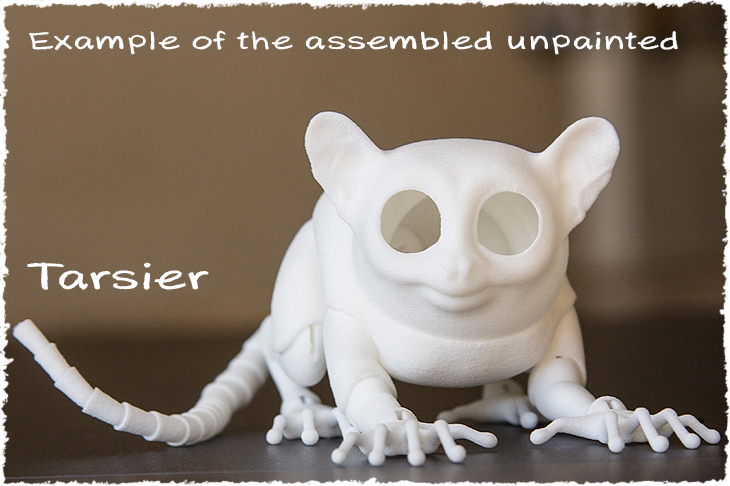

3D printing is carried out on an industrial 3D printer. The SLS (selective laser sintering) printing method is used. White plastic called polyamide is the material we use for printing our dolls. Before sintering it is powder, and after sintering the material becomes sufficiently strong, light and flexible, depending on the wall thickness of the product.

Printed parts have a slightly rough surface, which positively affects the tactile properties of animal dolls. Our partner is one of the best Russian companies printing on a 3D printer. They are professionals, whose technology and equipment allow to achieve high detail and excellent print quality.

When we receive the printed parts, they must be cleaned of powder and prepared for further processing.

Using several different techniques and materials to paint parts, we get smooth and beautiful color transitions, similar to realistic ones. We use matte varnish for the durability of paint.

The details are ready, but we need to make the eyes! We glue a print of an eye to the prepared blank. Then we drip some glaze on the glued printing. When the glaze hardens, we get volumetric realistic eyes.

Then we assemble the parts of the model on an elastic cord, paste neodymium magnets and assemble the mechanism of the Magnetic system. After assembling, we inspect everything carefully.

This is all! A doll is ready for delivery!